What Is a Gear Vibration Analysis and Why Is It Important?

Heavy-duty machines have characteristics that work perfectly with certain methods to avoid invasive and complicated procedures. Sometimes, problems are visible depending on the area that needs attention. Other times, the problem hides where no one can see it.

Development and efficiency rely heavily on a functional machine, and quickly finding a solution to a problem will minimize loss. Machines with a gearbox can benefit from a gear vibration analysis to detect abnormal conduct and find viable solutions without wasting resources.

What Is a Gear Vibration Analysis?

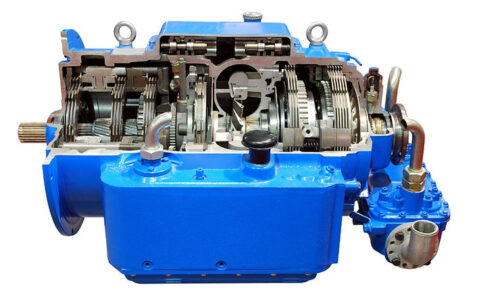

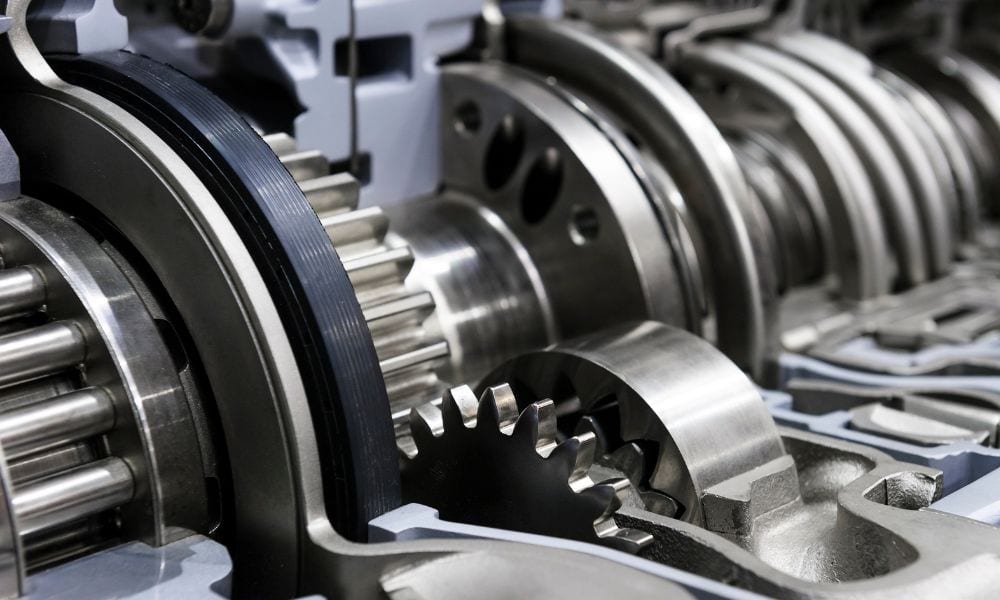

This process inspects industrial gearboxes with vibrations at different frequencies to detect damage to moving parts. Vibrations in a fully functional gearbox are consistent; a vibration analysis changes the pattern, alerting the operator if something is wrong.

A gearbox can experience different problems, and certain vibrations will provide clear answers for the best solution. Professionals know the pattern of a fully functional gearbox and will instantly detect a failing pattern.

Importance of a Gear Vibration Analysis

A gear vibration analysis is a maintenance technique that will optimize safety, development, and efficiency in your company to prevent downtime and damage. Constant monitoring of heavy-duty machines is the best solution to common problems, using fewer resources and preventing unwanted situations.

With fewer problems, consistency will stay at high levels, and utilizing this technique with the help of professionals will save you time and money. Gearbox repairs are sometimes necessary to keep your machines functional and safe. However, detecting problems before they worsen will let you save resources to keep your business thriving.

Scheduled Maintenance

Maintenance is important for machines to function properly; depending on usage and the size of your machines, you should schedule maintenance every six months. A gear vibration analysis has the perfect solutions, and the process takes around one hour to compile repetitive patterns.

At Churon Company, we have the essential materials to help your business stay on track and reach its short and long-term goals. Getting help from experienced professionals with unique techniques and knowledge will positively impact your business.

24/7 Emergency Service: (770) 757-3530

24/7 Emergency Service: (770) 757-3530

4811 Views

4811 Views  0

0