Repairing vs. Replacing Hydraulic Cylinders

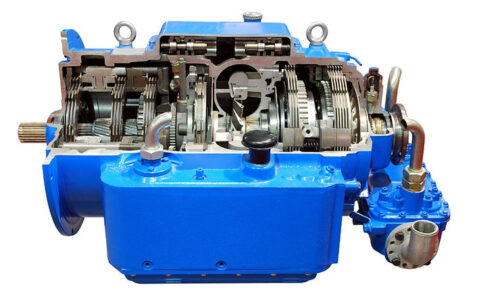

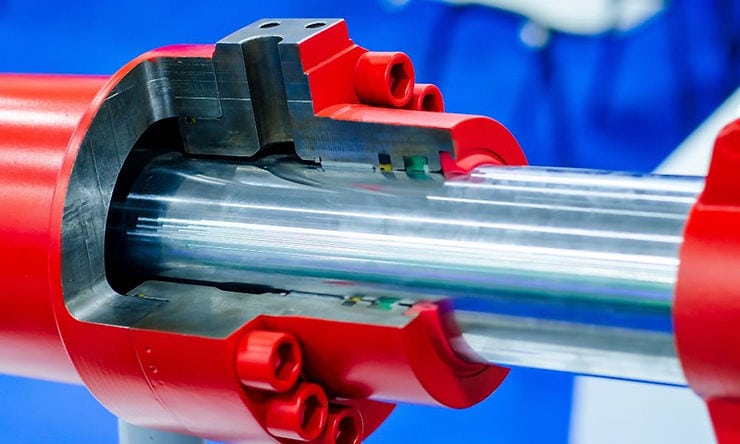

Heavy machinery and industrial equipment rely on hydraulic cylinders to power the movement of various mechanical elements. These critical components help various industries, from construction and mining to agriculture and manufacturing.

Like any mechanical system, hydraulic cylinders are susceptible to wear and tear over time, leading to reduced efficiency and potential breakdowns that could cost time and money. When faced with a problem like this, knowing the benefits of repairing vs. replacing hydraulic cylinders can help you maintain consistency, quality, and accurate results.

Cost-Effectiveness

One of the main benefits of choosing to repair hydraulic cylinders is cost-effectiveness. In most cases, repairing a malfunctioning cylinder is more affordable than purchasing a brand-new one. Repairing allows you to address specific issues while retaining the functional components of the cylinder, saving you a significant amount of time and money in the process.

Preserving Original Quality

Many hydraulic cylinders use high-quality materials and precision engineering to deliver accurate and steady results. Repairing the cylinder ensures you preserve the original manufacturer’s quality because the repaired components will remain consistent with the existing ones. This means you can maintain the performance and efficiency of the equipment without compromising on quality.

Faster Turnaround

When the hydraulic cylinder fails, downtime can lead to substantial financial losses for businesses. Repairing the cylinder often involves a faster turnaround time than replacing it entirely. Hydraulic cylinder repair services with skilled technicians and professional experience can diagnose and fix the problem quickly, reducing the overall downtime of your equipment.

Environmentally Friendly

In today’s environmentally conscious world, repairing instead of replacing hydraulic cylinders aligns with sustainable practices. By choosing to repair this element, you contribute to reducing waste and conserving resources because it prevents the premature disposal of an otherwise functional cylinder. Effective waste management is essential, and extending the lifespan of potentially hazardous elements will considerably help the environment.

Extensive Expertise Available

Hydraulic systems are intricate and require specialized knowledge for repair and maintenance. There are many skilled technicians equipped with the necessary expertise to handle a wide range of cylinder issues. Using their knowledge can bring your hydraulic cylinders back to life and extend their lifespan while helping you reach your company’s goals.

The choice between repairing and replacing hydraulic cylinders depends on several factors, including the extent of damage, budget constraints, equipment downtime, and long-term goals. For minor issues, repairing hydraulic cylinders is the best option. Whatever decision you make, you must work with reputable hydraulic repair services or manufacturers to ensure high-quality and reliable results.

24/7 Emergency Service: (770) 757-3530

24/7 Emergency Service: (770) 757-3530

23308 Views

23308 Views  0

0