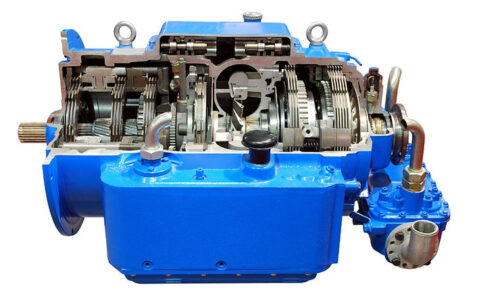

A Quick Guide to the Different Types of Industrial Gearboxes

Industrial gearboxes play an important role in environments where machinery and mechanical systems are necessary for operations. These devices transmit power inside machines and enable them to function. From manufacturing and mining to transportation and energy production, gearboxes ensure machines operate smoothly. This quick guide to the different types of industrial gearboxes will provide valuable information on their different functions so you can find one to match your machine’s needs.

Bevel Gearboxes

This type of gearbox is essential when the machine needs to transmit power between intersecting shafts. It uses bevel gears with conically shaped teeth to achieve this. Heavy-duty machinery like tractors, locomotives, and marine vessels rely on this gearbox when changes in direction are necessary.

Spur Gearboxes

Spur gearboxes are among the most straightforward and widely used type of gearboxes. They consist of two parallel shafts with gears that have straight teeth and transfer power between the shafts. Spur gearboxes are popular for their simplicity, durability, and cost-effectiveness. They are essential for conveyor systems and simple machinery that requires precise speed ratios.

Helical Gearboxes

Helical gearboxes operate similarly to spur gearboxes, but the teeth have a spiral pattern that offers more benefits. This design reduces noise and vibration, making helical gearboxes a popular choice for machines that require smooth operations, like elevators, automotive transmissions, and industrial mixers. The teeth require frequent inspections and maintenance, so working with an experienced gear machine shop will help you keep your helical gearbox in optimal condition.

Worm Gearboxes

Worm gearboxes are the best solution for machines that demand high reduction ratios and torque. They include a worm gear and a worm wheel to operate. The worm gear’s screw-like motion engages with the teeth, resulting in a compact and highly efficient gearbox. Industries that require heavy lifting, like construction and material handling, often use this type of gearbox for machinery.

Cycloidal Gearboxes

Cycloidal gearboxes, also known as harmonic drive gearboxes, are popular for their precision and high torque capabilities. They operate on the principle of flexible deformation, where a wave generator imparts motion to a flexible spline that drives the output shaft. Robotics, aerospace, and medical equipment rely heavily on this gearbox type for its accuracy. These different types of industrial gearboxes ensure a perfect match for every piece of machinery. Each type has distinct advantages, making them all suitable for various sectors. Knowing the differences will help you make smart decisions for your operations.

24/7 Emergency Service: (770) 757-3530

24/7 Emergency Service: (770) 757-3530

23311 Views

23311 Views  0

0